Jacquard fabrics: origins, ways to obtain them, and types

Jacquard fabrics are some of the most beautiful types of weaving of threads. If once was a luxurious material only royalty and nobility could afford, now it’s a commonplace in the textile sector. But we should highlight that we speak about jacquard fabric and jacquard because most people don’t know that jacquard is more a weaving technique than a type of material. Therefore, it’s a term used to define a range of fabrics with a pattern woven directly into the material (not printed, embroidered, or stamped over it). You can make jacquard from several fabrics, ranging from synthetic textiles to natural cotton and silk.

If you’ve ever shopped for textiles, you most likely saw jacquards without realising it. This article provides information about the history of the jacquard, how it’s made and its common uses.

The origins of jacquard fabric

Jacquards, or brocades, as they were known in the past, first appeared in the 4th century Byzantium. As the silk weaving methods evolved over the centuries, starting with the 6th century, makers started to create more intricate models of luxurious fabrics that quickly gained popularity. During those times, brocades were decorated with natural motifs like plants and flowers, mixed with metallic threads to create greater visual interest and texture. Some textiles even integrated jewels and beading, looking sumptuous and opulent. However, the process of making these materials was back-breaking for the weavers, which were rare and expensive. Brocades became high-end materials, and the church and royalty used them to symbolize their wealth and status.

During the Renaissance, Italy was the finest producer of brocades, and buyers from around Europe would purchase them at expensive prices. The nobility favoured arabesque patterns and swirling scrolls, which quickly became a symbol of wealth. Some people preferred to have their family crests woven into the brocades for their garments and home décor. Unusual animal motifs were among the most popular patterns during the Renaissance, but we cannot tell for sure if they contained some private symbolism for the buyers that got lost until the present. Few samples of fine textiles exist from that era, so we must use paintings as references when we document the way they looked.

During the 1700s, brocades were made on large looms by two workers, a master weaver and a draw boy. The process was challenging and slow, and only 2 square inches of fabric were made in a full day. The draw boys were also exposed to safety hazards because they had to lift half their body weight in weaving reeds, action which left many of them crippled after a couple of years of work. One of these draw boys, Joseph Marie Jacquard, discovered the solution to make a machine to create brocade patterns and saved workers from the torturous process. He promoted the idea of using punch cards to instruct the loom on which threads to raise at determined points and create intricate patterns. His ingenious discovery is the antecedent to the present digital machines. The first mechanised model debuted in 1804 and was named after the man who discovered and pioneered it. The innovative machine enabled weavers to create a wide range of models in shorter times and transformed brocade from a high-end fabric accessible only to the nobility to a common material everyone could purchase.

What you should know about jacquard weaving

Nowadays, weaving looms come in several sizes and shapes, from floor looms to inkle, table looms, and jacquard looms; you can find an extensive range. The main factor distinguishing one from another is how the weaver raises warp threads to make a shed to enable an interlacing weft to pass to weave the material. If you inspect jacquard fabrics closely, you’ll notice some fine lines of threads and yarns interlaced. The longitudinal threads that run down the material are named warps, while the ones that run across the width are the fills or wefts. A loom is a machine that weaves the threads together to create a patterned piece of fabric.

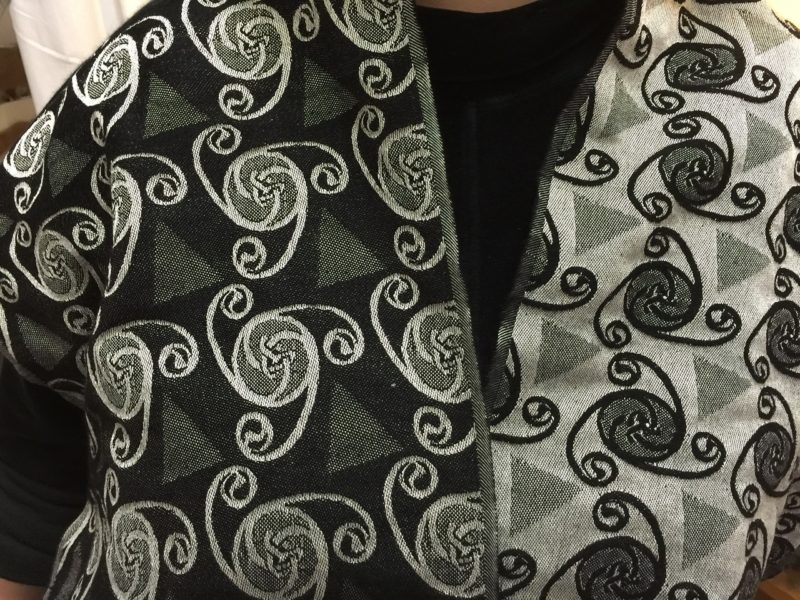

Modern technology enables makers to create jacquard fabrics with intricate patterns, so you’ll find an infinite number of models when you shop. Even if the machines evolved, the jacquard technique still uses the same principle as the first piece of equipment used. As the first machine, the modern ones create fabrics by passing weft threads under and over warp threads to create a criss-cross model of yarns. However, the Jacquard method has a twist in comparison with the other ones; it picks a weave pattern that mixes the ratio or over and under threads, delivering unique textures. Jacquard weaving utilises pre-designed weave patterns and coloured threads to make complex designs with a tapestry-like appearance and subtle texture. This technique is different from classic ones because it enables the design of elaborated patterns.

The industrialisation and reduction of production costs made jacquards more affordable. Looms are quite productive even if the principle of making the material remains the same. The Jacquard loom lifts individual threads and can create textiles with intricate patterns. The weaver can make plain weave items on a Jacquard loom, rigid heddle, 16-shaft looms, and two-shaft looms. The traditional Jacquard machines come with a Jacquard head and a lifting device.

Types of jacquards

The jacquard weave is categorised into three types of fabrics:

– Damask – a finer version of brocade that is usually created with a single-coloured thread. It’s regularly used in synthetic fibre production and fibre blends.

– Brocade – widely used in upholstery and fashion, as it’s heavier than other materials. Brocade features raised patterns due to the multi-coloured threads utilised to produce it. It has one of the richest designs in the textile sector.

– Matelassé fabric – is obtained by using cotton, rayon, or silk. It usually has a stretchy surface.

Final thoughts

The latest advancements in technology transformed jacquard weaving into a process completed with the help of modern computers. The machines have thousands of hooks and ease the production process, making it less time-consuming.